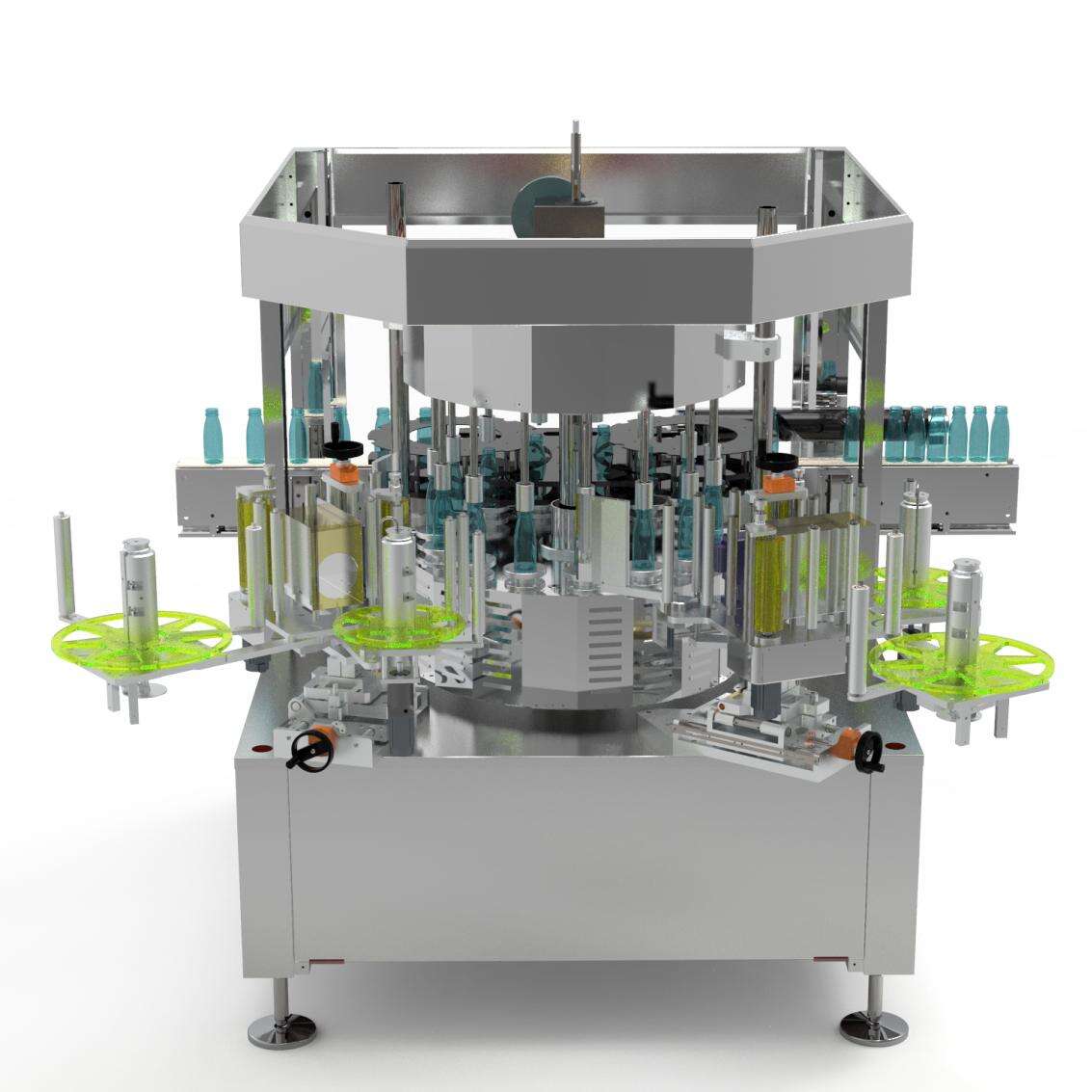

High speed rotary way wrap around labeler

Model : XTHZ-8

Capacity :200-600pcs/min

Application: round square flat bottle/jars/cans...

Labeling position: wrap around,Front&back, Multi-Sides , Neck...

Control system : Servo motor

Optional device : Printer

Voltage : 110V/220V/380V

Press bottle head : 8pcs, 10pcs , 12pcs for choose

- Overview

- Video

- Parameter

- Electrical Brand

- Related Products

● High speed rotary way labeling machine, with 6 heads 8 heads or 12 heads can choose;

● Suit for round bottle labeling wrap around ;

● Suit for square bottle labeling on different sides with one label or two labels;

Control system

① PLC and man-machine interface use well-known brands of electrical components to ensure that the electrical quality and performance, improve service life. In addition to the touch screen can display the production speed, single class output, running status, fault status, handover message board, but also directly on the touch screen for a variety of parameter settings operation.

② Labeling machine adopts automatic frequency conversion control technology,can meet the various speed changes, to ensure smooth and accurate labeling.

③ No bottle no label, so that more accurate labeling to prevent loss of packaging.

④ Electronic and pneumatic facilities are fully equipped and can be directly connected to the workshop facilities.

⑤ All electronic and pneumatic control circuits according to CE international standards, the main components using imported components

⑥ Main motor is controlled by the inverter and a group of sensors. The operating speed varies according to the operation of the labeling machine and the speed of production.

⑦ Electrical connection with other equipment failure or block bottle, labeling machine system provide a passive contact signal to the device.

⑧ cast parts, carbon steel, aluminum parts have been through multi-layer anti-rust treatment.

Machine Features

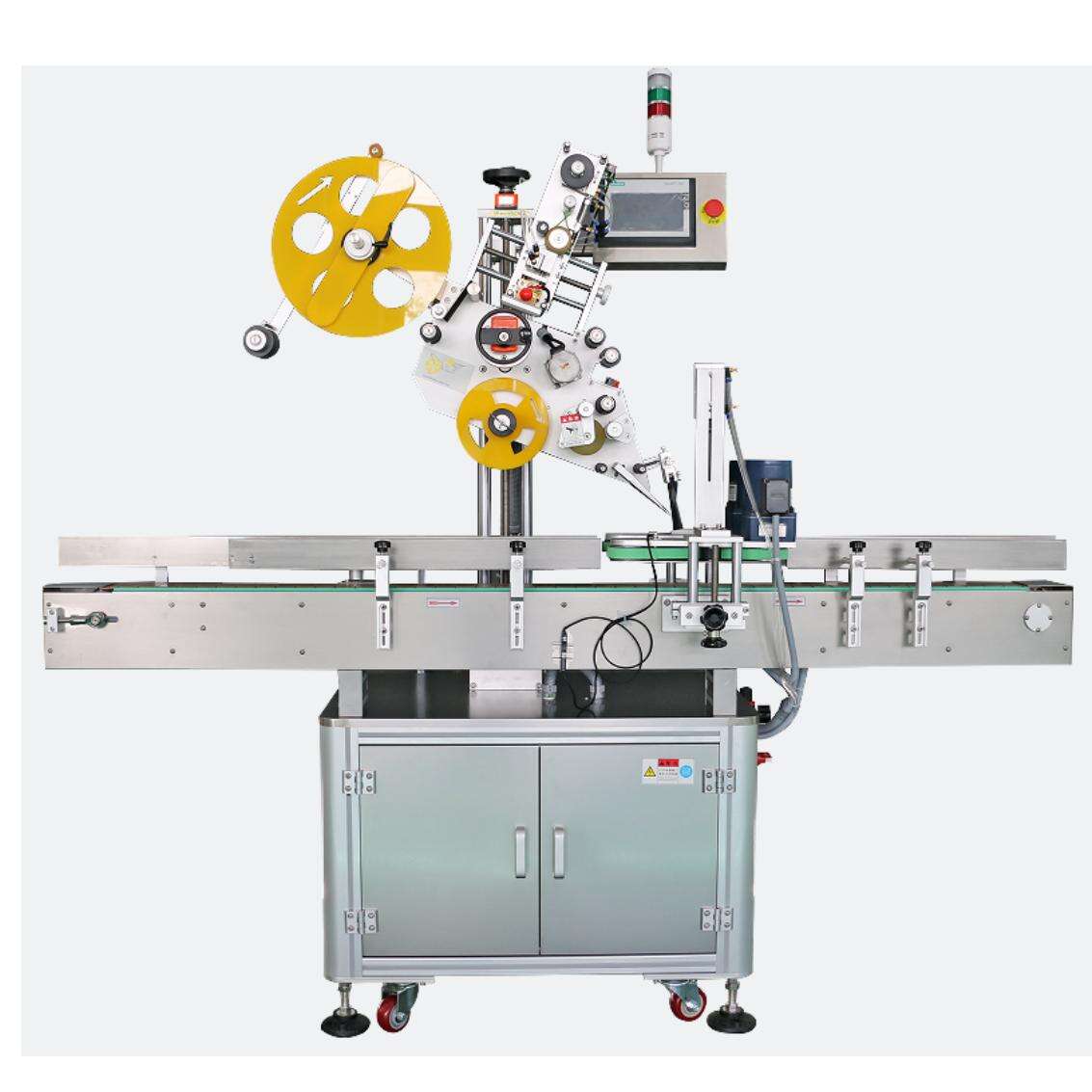

Accurate labeling at various speed;

Sensor positioning is optional;

Visual positioning is optional

Replace bottle no need to replace any parts of labeling engine, only adjust the operating parameters is ok, make sure process more simple;

Small amount of damage label(reach to the international advanced standards)

Servo drive send label, labeling in high accuracy;

Full automatic logic program control, easy to control, easy to adjust;

Put label and collection label with independent drive to ensure smooth operation of the servo drive;

Can add more labeling engines, Achieve change label and machine not stop working function ;

Spare parts introduction

1)Labeling engine :

Main send label servo motor, use the motion control servo, high performance, high response;

Send label motor is the Independent servo motor operation, with the label storage warehouse, label can not broken in high speed ;

Collection label motor also the independent servo motor operation, with the angle sensor, smooth collection;

2)Bottle holder :

Depends on client bottle size and shape, design the most suitable press bottle heads and bottle holders, with perfect labeling effect;

Parameter

| Model | XTHZ600-8S |

| Driving Mode | Servo motor |

| Press bottle head | 8 pcs |

| Yield(pcs/min) | 4000-10000 P/H( can adjustable ) |

| Operating direction | Left or Right |

| Conveyor Speed(m/min) | ≤60 |

| Labeling Accuracy | ±1.0 mm |

| Label roll inner diameter | 76 mm |

| Label roll outer diameter | 400 mm(max) |

| The suitable size of label | H: 15-250 mm L: 20-250 mm |

| Compressed air consumption | 300NL/MIN |

| Compressed air working pressure | 4bar |

| Use ambient temperature | 0-50℃ |

| Environmental relative humidity | 15-95% |

| Power(w) | 11000W |

| Voltage | AC110-380V 50/60HZ |

| Weight(kg) | 2300 |

| Conveyor height | 1150±50mm (Height can customized) |

| Machine size | 2400(L) 1700(W) 2100(H)mm |

Electrical Brand

| No | Items | Model | Brand | Qty |

| 1 | HMI | 2711P-T10C21D8S | AB(American) | 1 set |

| 2 | PLC | 1769-L27ERM-QBFC1B | AB(American) | 1set |

| 3 | communication module | 1769-SM2 | AB(American) | 1set |

| 4 | K350 servo drivers | 2097-V31PR0-LM | AB(American) | 1set |

| 5 | MPL servo motor | MPL-A1530U-VJ72AA | AB(American) | 1set |

| 6 | PF527 Inverter | 25C-D6P0N104 | AB(American) | 1set |

| 7 | K350 Servo IO board | 2097-TB1 | AB(American) | 1set |

| 8 | K3 server Driver | 2071-AP4 | AB(American) | 8sets |

| 9 | K3 servo motor | TL-A230P-BJ32AA | AB(American) | 8sets |

| 10 | PF-4M Inverter | 22F-D2P5N103 | AB(American) | 1set |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY