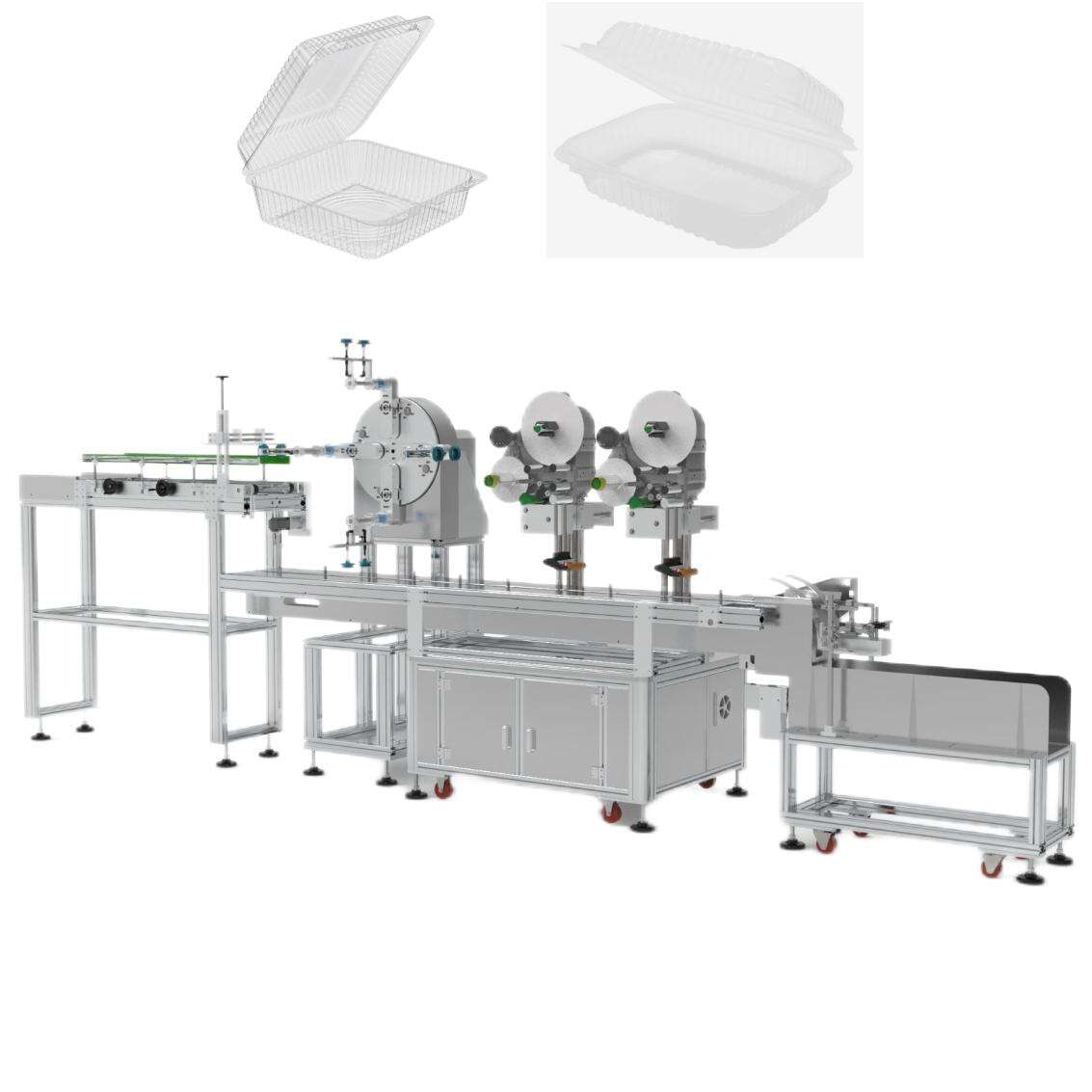

Clamshell customized labeling machine

Model : ELM-D-A

Capacity :50-150pcs/min

Application: Empty Tray, clamshell and so on

Labeling position: On top, bottom, top & bottom surface

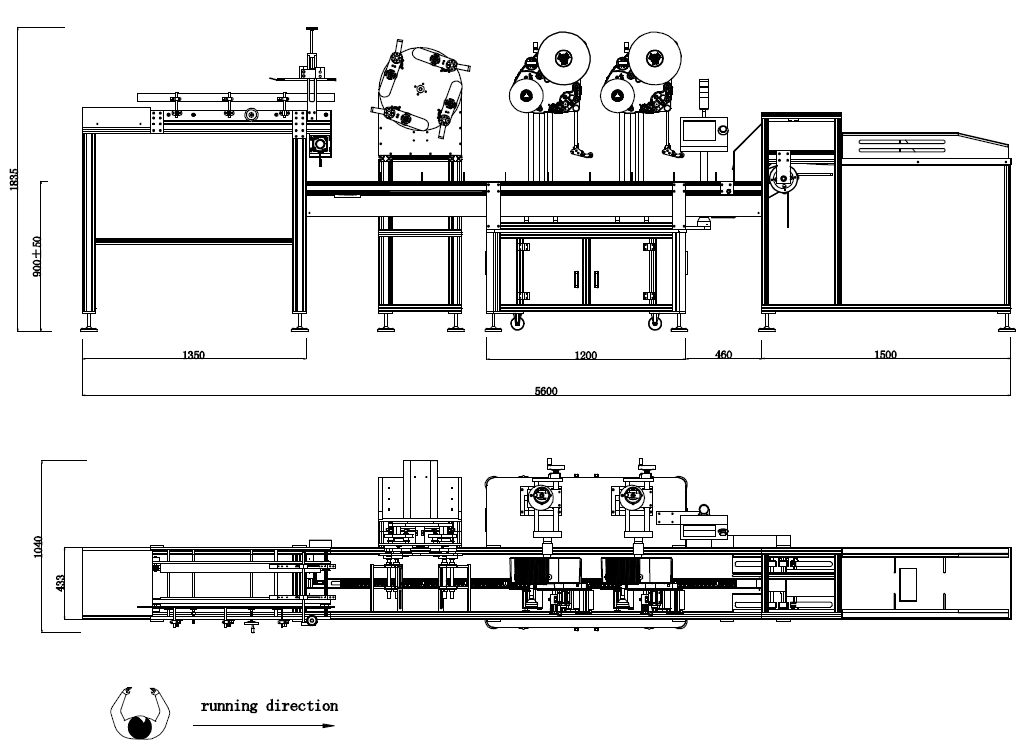

Machine size: 5600x1040x1835mm

Control system : Servo & German novexx for choose

Voltage : 110V/220V/380V

Optional device : auto feeding, collection device

Machine can customized depends on client labeling objects

- Overview

- Video

- Parameter

- Electrical Brand

- Related Products

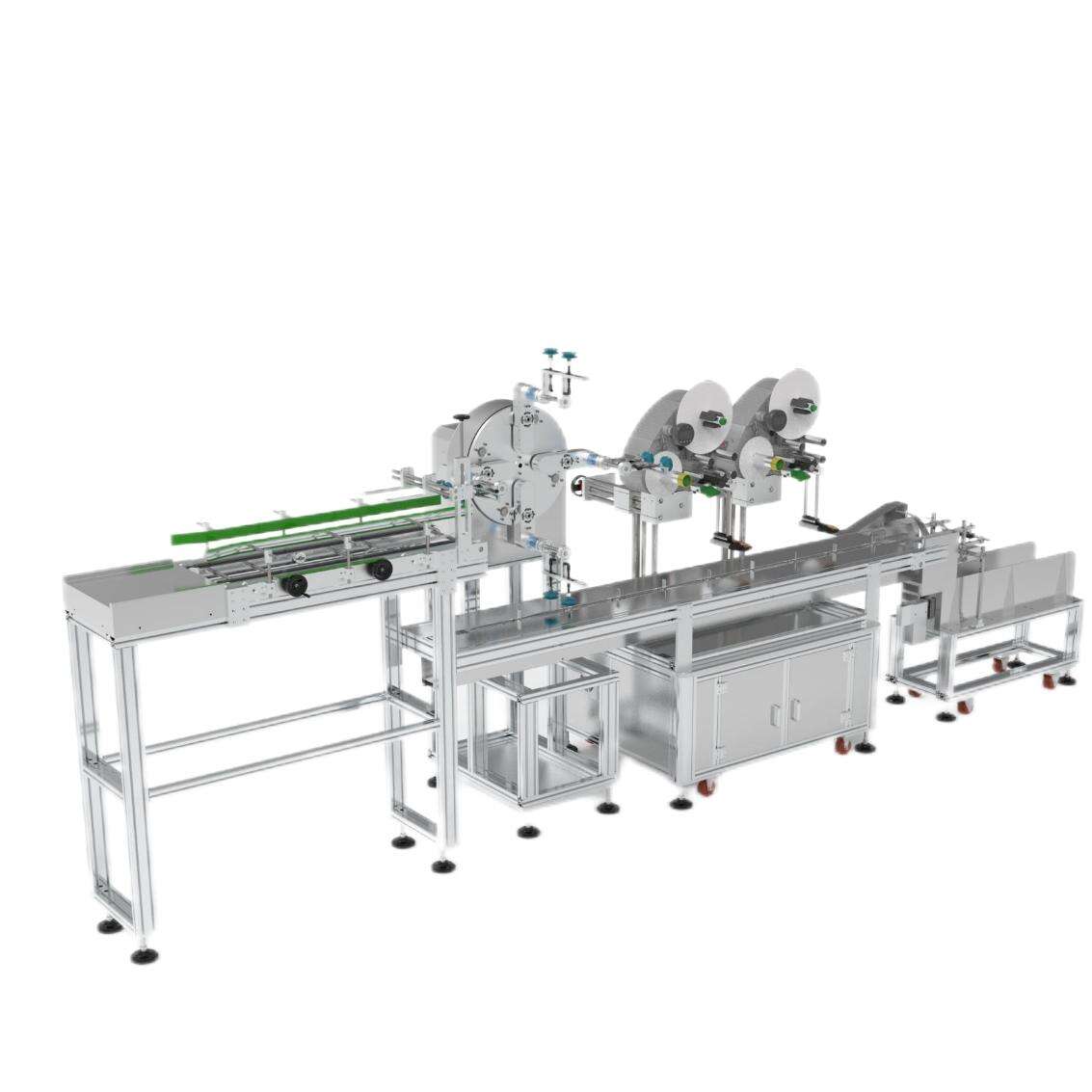

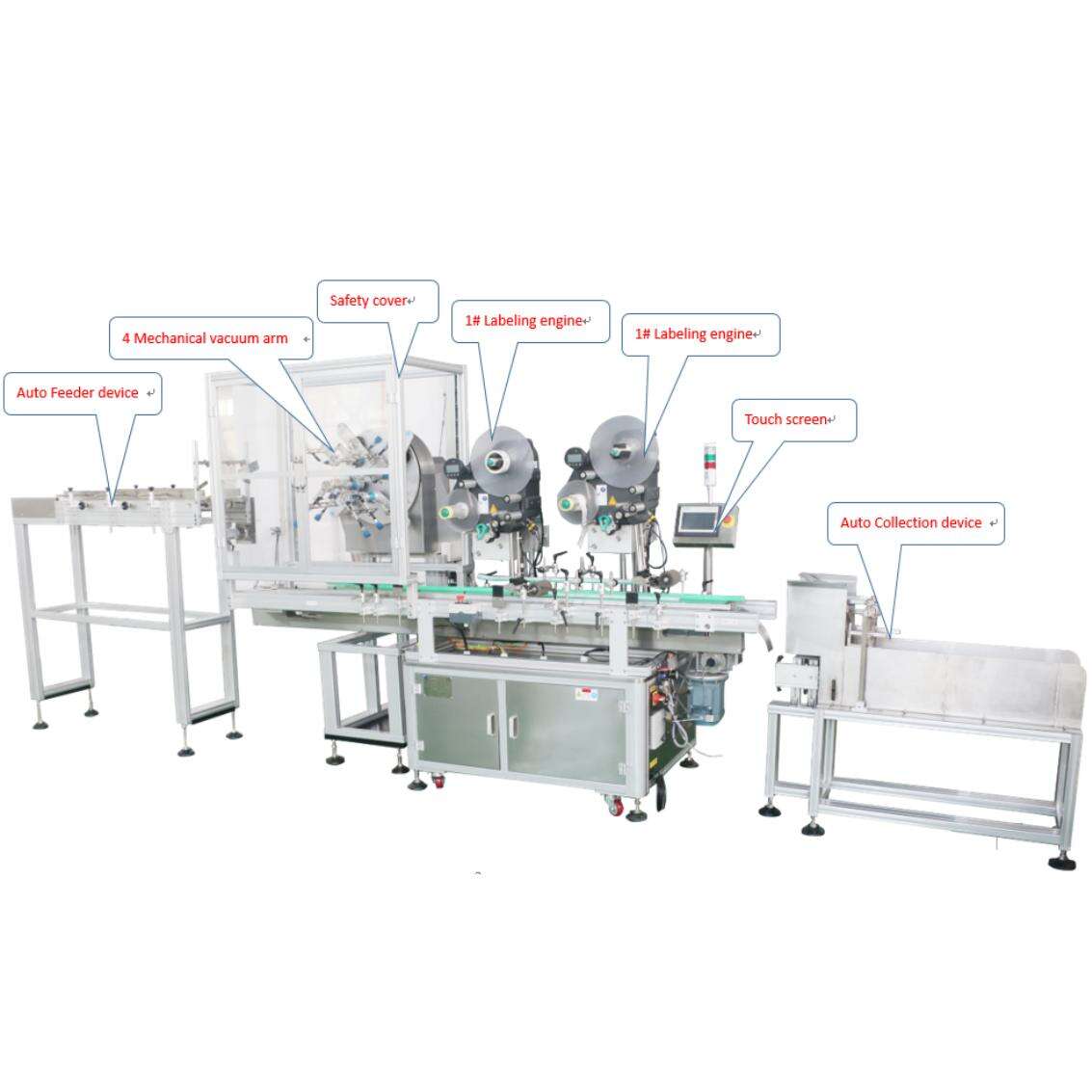

Working process

Worker put a dozen of clamshell on feeder device, delivery to exit part one by one;

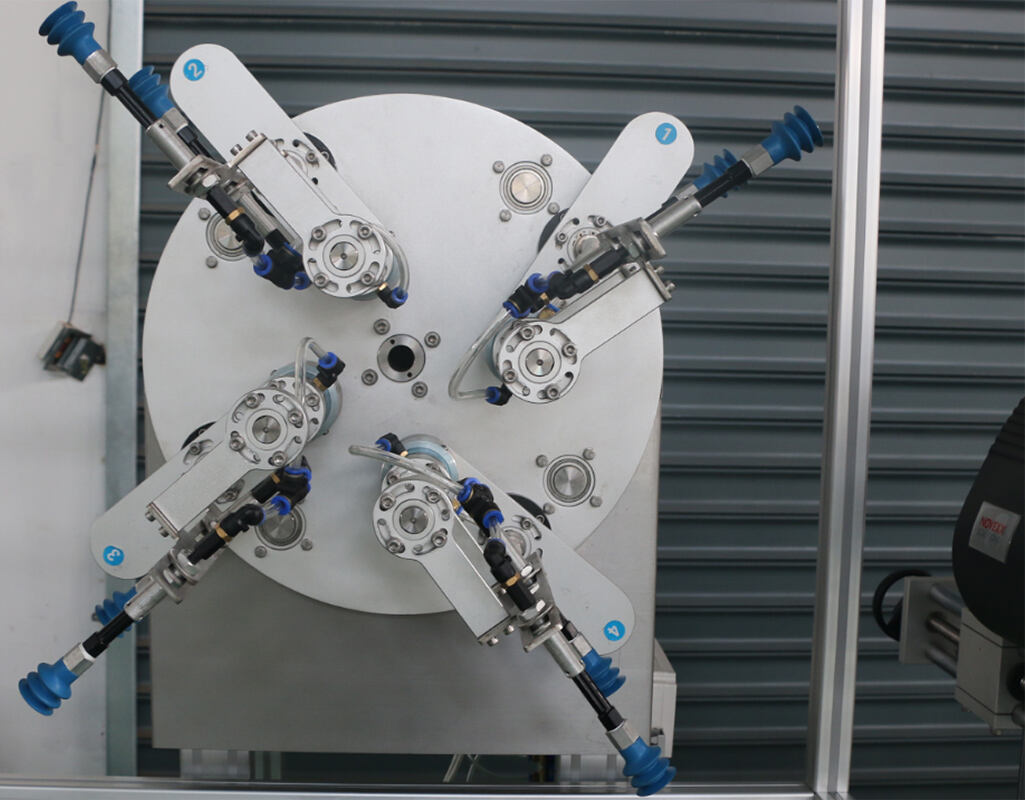

The 4 Mechanical vacuum arms suck clamshell on conveyor one by one and keep then in same distance, then delivery to the labeling part;

When sensor check clamshell, 1# and 2# labeling engine working, put the two labels on clamshell two surface, brush label sponge the label more smooth. Labeling finish;

Clamshell go on delivery to the end part of conveyor, flip mechanism put clamshell into collection device, after the collection device is full, worker take them out directly;

Spare parts function

①Customized conveyor

②4 pcs Mechanical vacuum arm

Machine sketch map view

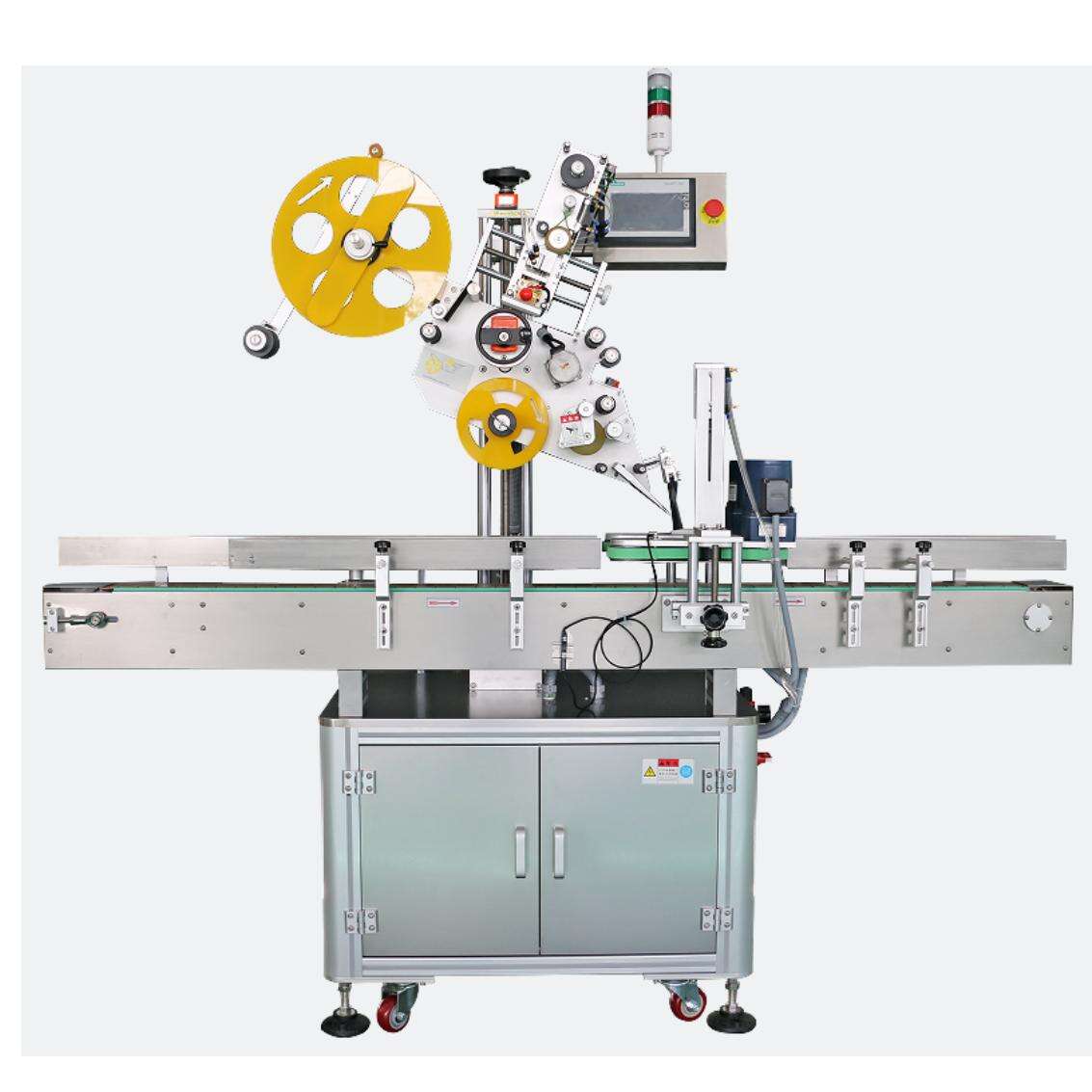

Parameter

| Model | ELM-D-ALS204 |

| Driving Mode | German Novexx labeling engine |

| Yield(pcs/min) | 90-120 (depends on egg box and label size) |

| Operating direction | Left or Right |

| Labeling Accuracy | ±1.0 mm |

| Inner diameter of label roll | 76 mm |

| Outer diameter of label roll | 350 mm(max) |

| Suitable label size | W: 10-110 mm L: 10-300 mm |

| Suitable container box size | Can customized |

| Printer use air | 5kg/cm ² |

| Voltage (can customized) | 110V/220V/380V |

| Machine size | 5600(L) 1830 (W) 1040 (H) mm |

Electrical Brand

| No | Name | Brand |

| 1 | HMI (Touch screen) | SIEMENS |

| 2 | programmable control (PLC) | SIEMENS |

| 3 | Labeling engine | NOVEXX ALS204 |

| 4 | Auto feeder device | Panisonic |

| 5 | Auto collection stacker device | Panisonic |

| 6 | Sensor (check container) | Japan KEYENCE |

| 7 | Sensor (check label) | German LEUZE |

| 8 | Inverter | DELTA |

| 9 | Conveyor servo motor | DELTA |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY