Bottle Front & back and neck labeler

Model : DLM-SLM-A

Capacity :30-150pcs/min

Application: bottle,jars, cans

Labeling position: On front back and neck sides with three stickers

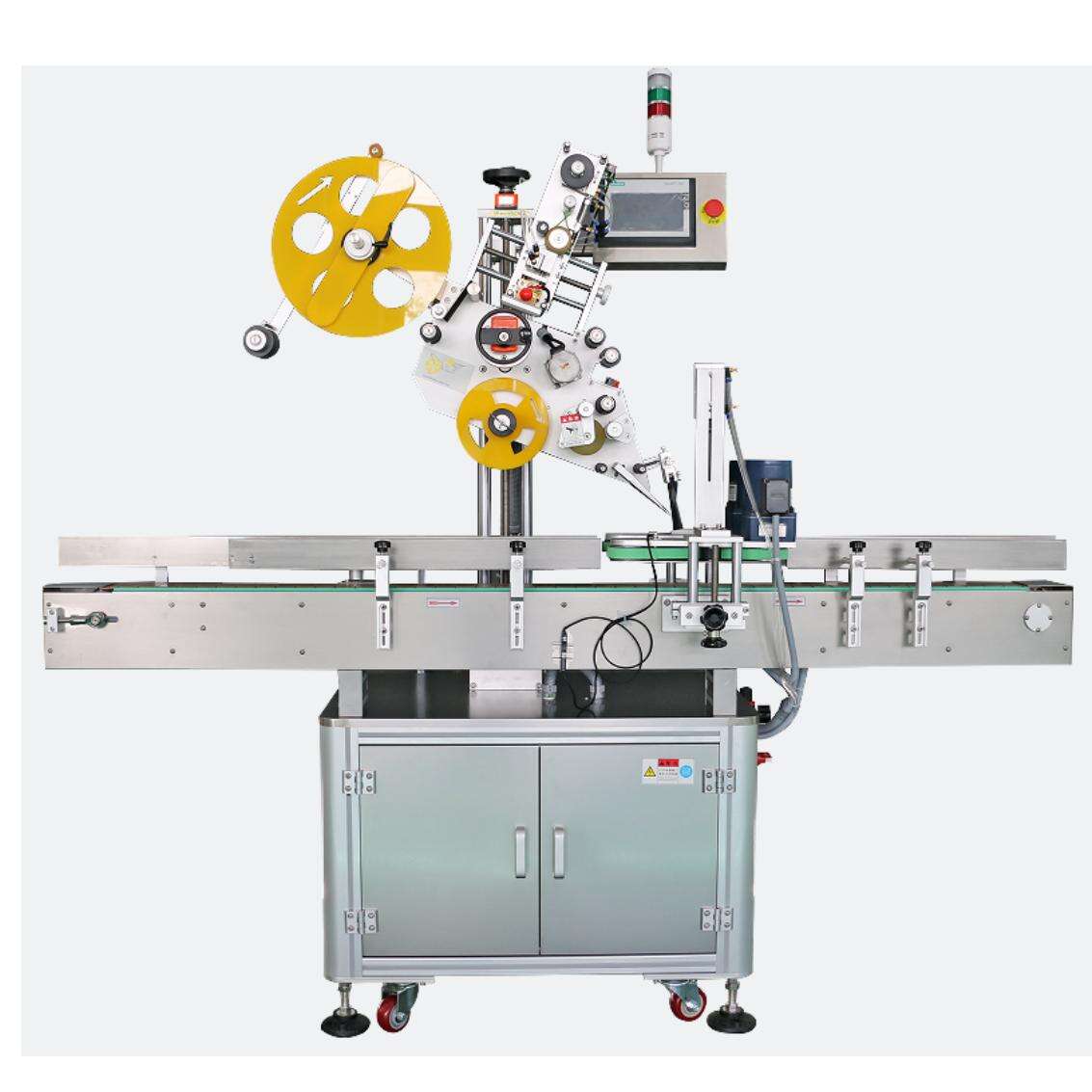

Control system : Panisonic Servo control labeling engine

Label material: opaque or transparent label

Optional device : Rolling device, printer ,turntable

Voltage : 110V/220V/380V

Machine can customized depends on client labeling objects size and requirement.

- Overview

- Video

- Parameter

- Electrical Brand

- Related Products

INTRODUCTION

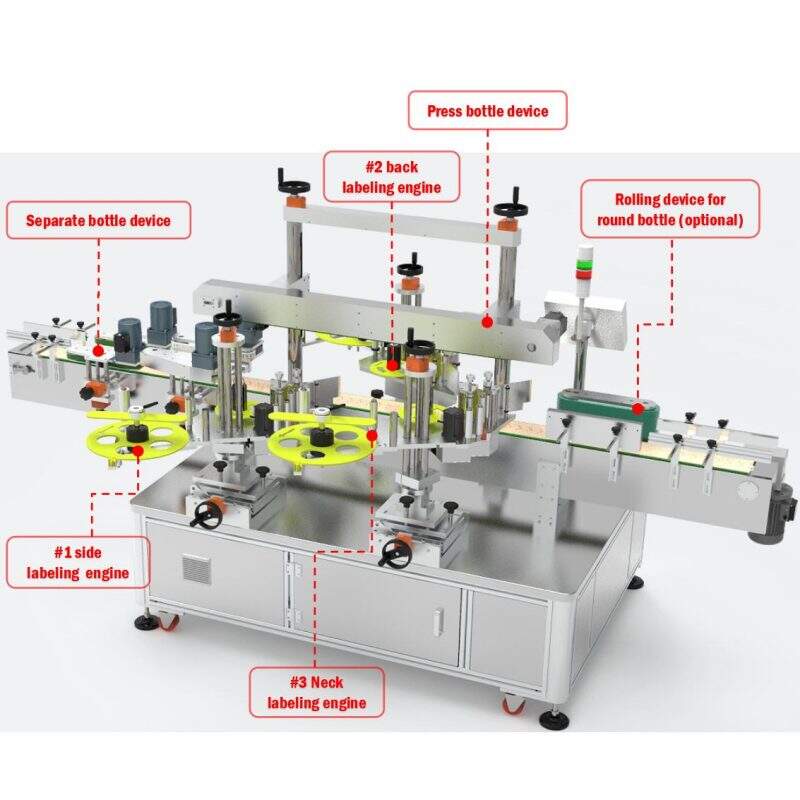

● Suit for bottle labeling on front back and neck surface, with three stickers;

● With rolling label device, suit for round bottle labeling wrap around;

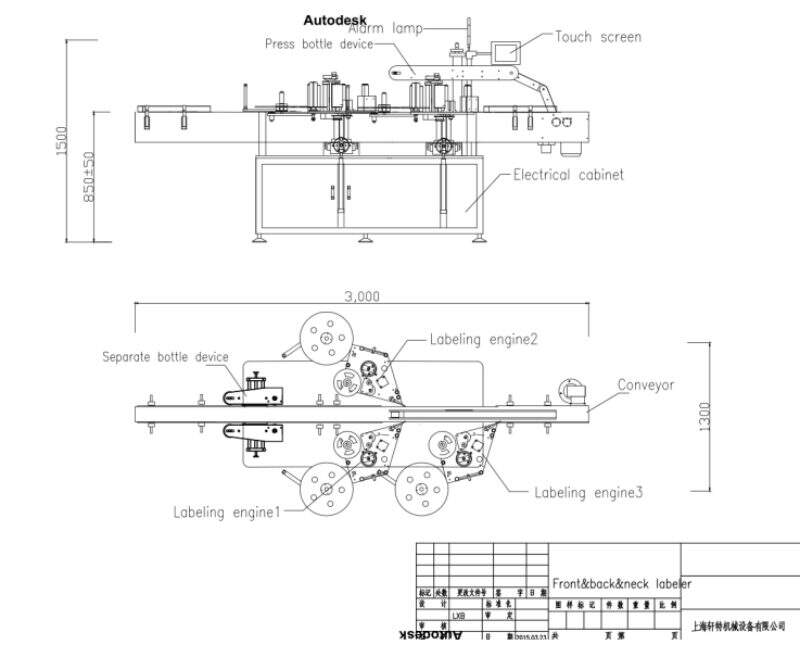

Machine sketch map

Parameter

| Model | DLM-SLM-A |

| Driving Mode | Servo motor |

| Yield(pcs/min) | 30-120 (depends on bottle and label size) |

| Operating direction | Left or Right |

| Labeling Accuracy | ±1.0 mm |

| Inner diameter of label roll | 76 mm |

| Outer diameter of label roll | 350 mm(max) |

| Suitable label size | W: 15-150 mm L:15-250 mm |

| Suitable bottle size | W:(Diameter): 20-90mm , H:30-300mm |

| Printer use air | 5kg/cm ² |

| Voltage (can customized) | 110V/220V/380V |

| Machine size | 3000(L) 1500 (W) 1600 (H) mm |

Electrical Brand

| No | Name | Brand |

| 1 | HMI (Touch screen) | SIEMENS |

| 2 | PLC | SIEMENS |

| 3 | Servo motor and driver | Panisonic |

| 4 | Sensor (check bottle) | Japan KEYENCE |

| 5 | Sensor (check label) | German LEUZE |

| 6 | Inverter | DELTA |

| 7 | Separate bottle motor | JSCC |

| 8 | Tidy bottle motor | JSCC |

| 9 | Press bottle motor | JSCC |

| 10 | Conveyor motor | Switzerland ABB |

| 11 | Encoder | German SICK |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY