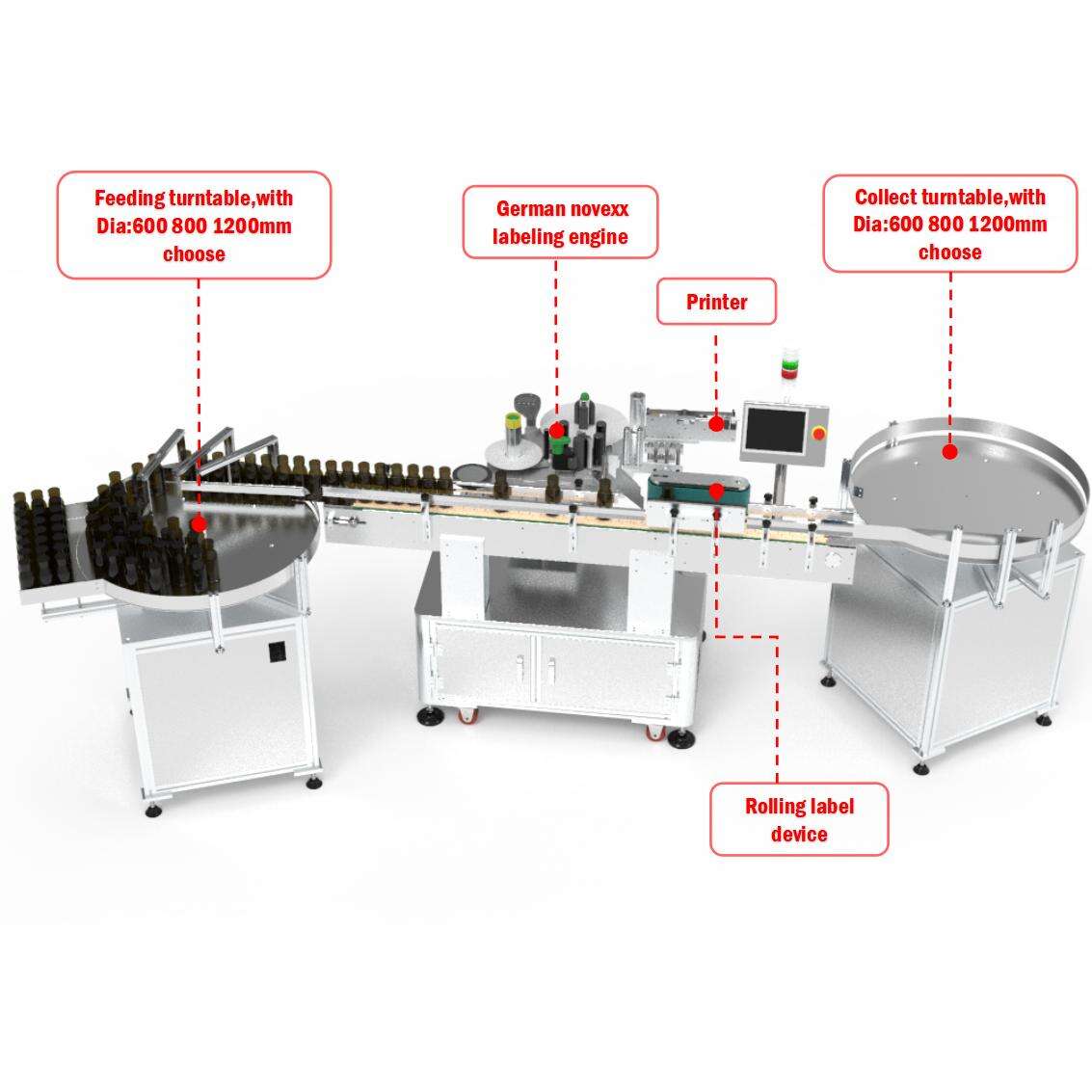

Auto round bottle jars cans wrap around labeler

Model : PLM-A

Capacity :40-200pcs/min

Application: Round bottle,jars,cans,Cylinder

Labeling position: wrap around

Machine size: 1800x800x1300mm

Voltage : 110V/220V/380V

Control system : Step & Servo & German NOVEXX for choose

Optional device : Printer, Turntable ,Working table plate

Customize : Machine conveyor and size can made as client need

- Overview

- Video

- Parameter

- Electrical Brand

- Related Products

Wrap-around labeling solution

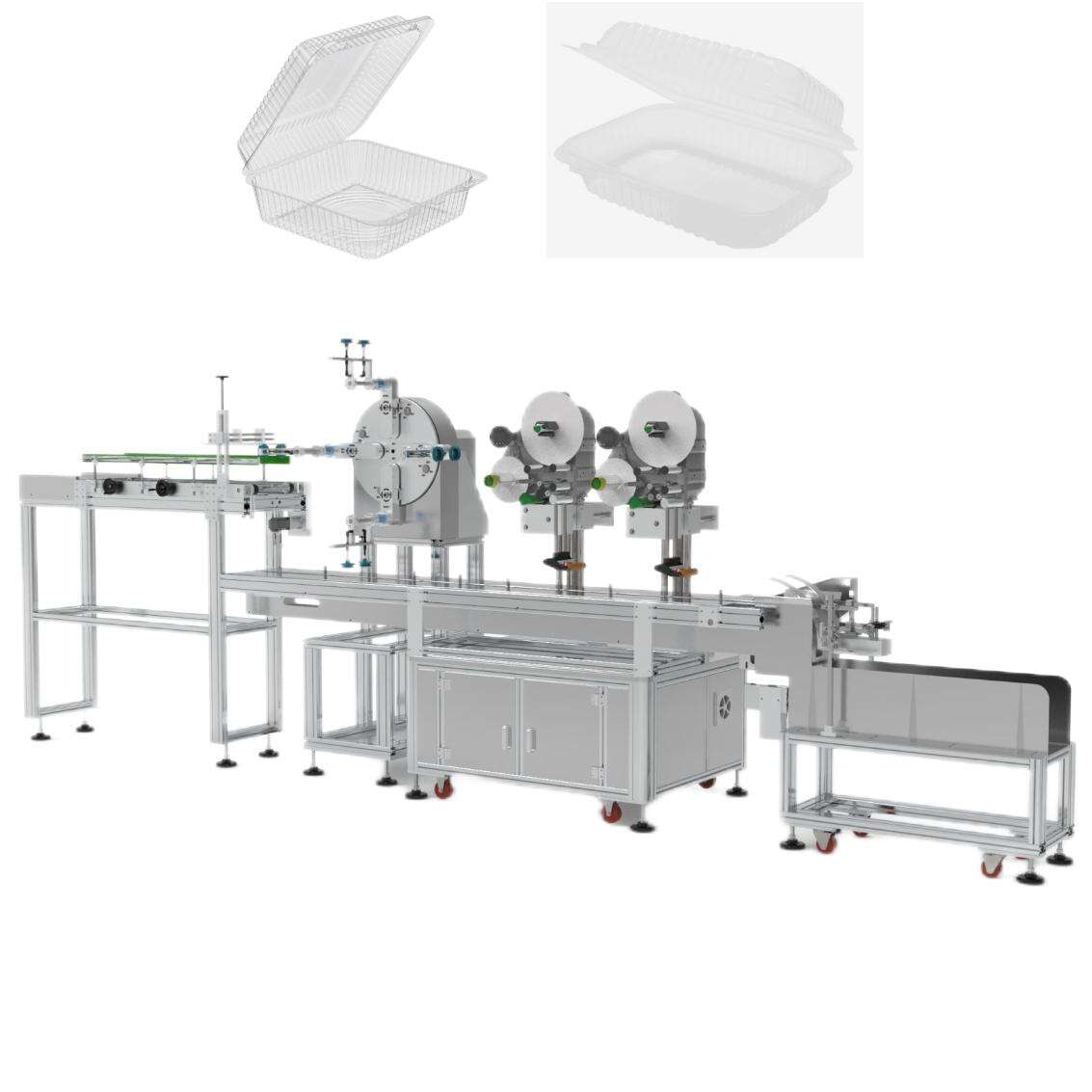

1. A large area of application for round bottle/jars/cans labeling,usually labeled wrap around ;

2. In pharmaceutical is indispensable for vial labeling, bill bottle labeling ;

3. Labeling of cosmetics, shampoo bottle wrap around labeling, detergent round bottle labeling;

4. Confectionery and good labeling from jam in jars to cereals in cans labeling wrap around ;

5. Chemical products paint round cans labeling and much more ;

Optional Features

1. Turntable at in-feeding and out-feeding for round bottle labeling machine ;

2. One more labeling engine for machine not stop working when change label roll;

3. Visual camera detection function for printing content ;

4. Sensor for label use up, machine alarm ;

5. Sensor for product lack of label , tick it out ;

6. Machine height can customized depends on client production line.

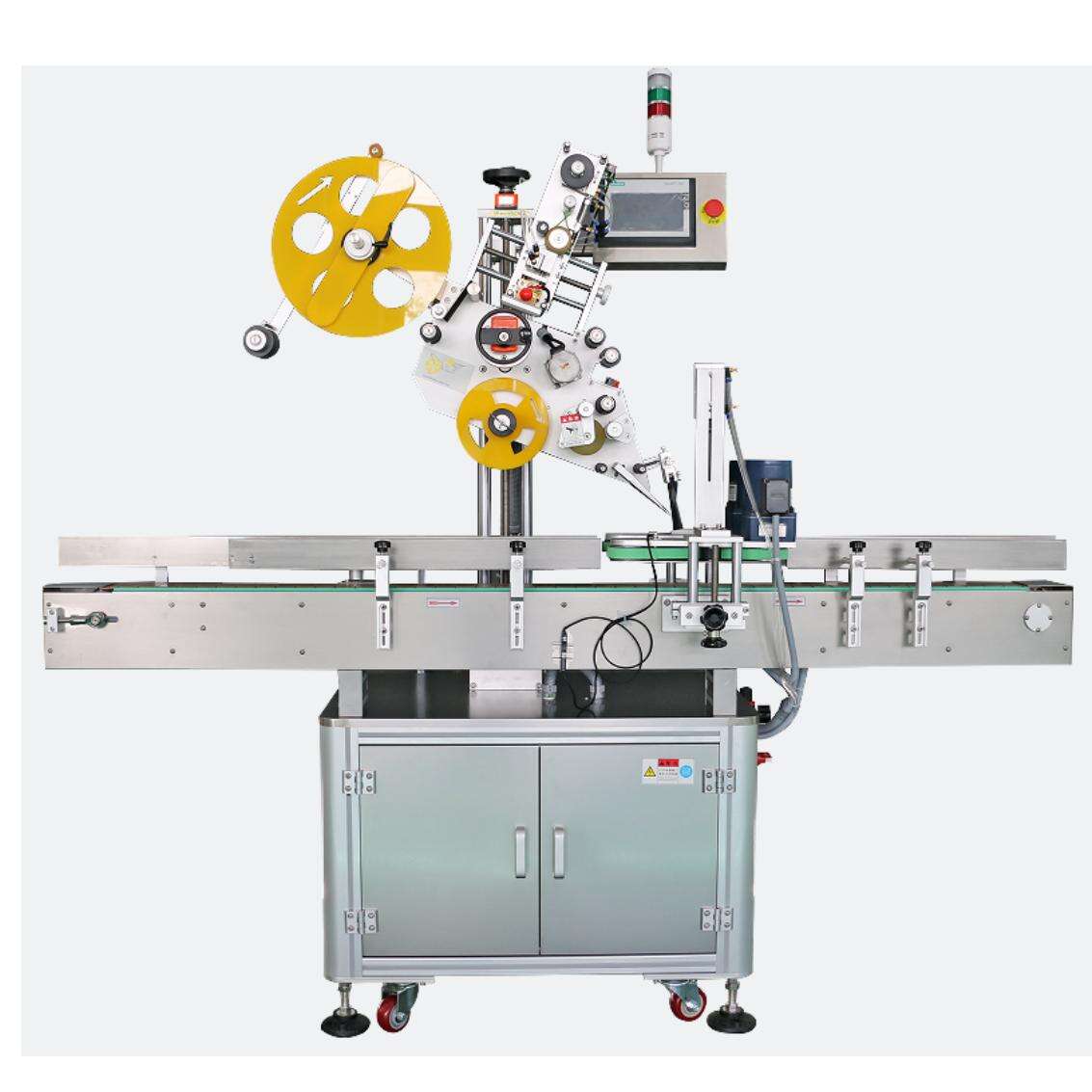

Working process

Bottles move to separate bottle device, keep bottles in same distance;

When sensor check bottle, send signal to PLC, PLC receive signal deal with information first, then output signal to servo motor driver send label.

Brush label device past label on bottle one part first, then bottle rolling around in the roll label device, brush label on bottle body for around, labeling finish.

Parameter

| Model | PLM-A & PLM-ALS204 |

| Driving Mode | Servo motor & German novexx labeling engine |

| Yield(pcs/min) | 30-200 (depends on bottle and label size) |

| Operating direction | Left or Right |

| Labeling Accuracy | ±1.0 mm |

| Inner diameter of label roll | 76 mm |

| Outer diameter of label roll | 350 mm(max) |

| Suitable label size | H: 10-150 mm L: 10-300 mm |

| Suitable bottle size | Dia: 28-100mm,H: 30-260mm |

| Printer use air | 5kg/cm ² |

| Voltage (can customized) | 110V/220V/380V |

| Power(w) | 650W |

| Machine size | 1800(L) 800 (W) 1300 (H) mm |

Electrical Brand

| No | Name | Brand |

| 1 | HMI (Touch screen) | SIEMENS |

| 2 | PLC | SIEMENS |

| 3 | Servo motor and driver | Panisonic & NOVEXX ALS204 |

| 4 | Sensor (check bottle) | Japan KEYENCE |

| 5 | Sensor (check label) | German LEUZE |

| 6 | Inverter | DELTA |

| 7 | Separate bottle motor | German JSCC |

| 8 | Roll label motor | German JSCC |

| 9 | Conveyor motor | German JSCC |

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY